Once the active ingredient of the herbicide has been developed it has to be presented to the user in a format which will be both economical and effective. Many companies provide the growers with a herbicide in different formulations depending on the application. The different formulations are used in order to vary the volatility, solubility, toxicity, stickiness, pressure and weight of the active ingredients. The type of formulation is adjusted by adding an adjuvant and/or surfactant to the chemical. An adjuvant is any substance which is added to the herbicide formulation in order to modify its active characteristics. A surfactant is any material which is added to the formulation which will improve the:

- Emulsifying

- Dispersing

- Spreading

- Wetting and other properties.

The surfactants action is mainly based on modifying the surface tension characteristics of the emulsion. An adjuvant and surfactant are both passive or inactive ingredients of a herbicide. The various types of formulations are summarized in the table below.

A summary of the various types of formulations, their descriptions and commonly used abbreviations| Formulation type | Description | Abbreviation |

|---|---|---|

| Emulsions | Emulsifiable concentrate | EC |

| Emulsion, oil in water | EW | |

| Suspo-emulsion | SE | |

| Granules | Granule | GR |

| Macro granule | GG | |

| Water soluble granule | SG | |

| Water dispersible granule | WG | |

| Powders | Soluble powder | SP |

| Wettable powder | WP | |

| Solutions | Soluble concentrates | SL |

| Suspensions | Capsule suspension | CS |

| Suspension concentrate | SC |

Emulsifiable concentrates

An emulsion is a liquid in which two or more liquids are mixed and each component retains it own identity. Some emulsions show the two liquids from which it is made if it is left still for a while. When agitated they have a milky appearance. When the active ingredient is oil based and is dispersed in water, o/w solutions, it is referred to as the dispersed phase and the water is referred to as being in the continuous phase.

When the oil based compound is used as the continuous phase and the active ingredient is water based, w/o solutions, it is called an inverted emulsion. Inverted emulsions are thick and viscous. Their primary purpose is to reduce spray drift.

Granules and pellets

Granules are smaller than pellets. Granules can be applied mechanically whereas pellets are design to be spread by hand or it is used for spot treatments. Granules and pellets have advantages over liquids.

- They do not require water

- The equipment used to apply these herbicides are cheaper and easier to use and maintain than spray equipment

- Granules can be added even if there is an organic mulch on the ground.

- The granules will not damage any plants on which it falls

- However there are some disadvantages.

Granules and pellets are more bulkier and weigh more for the same effect.

- They are often more expensive to apply.

- It is more difficult to calibrate the equipment and even distribution is difficult.

The carriers used in granules can be:

- Clays

- Vermiculite

- Perlite

- Starch

- Organic plant residues and

- Dried fertilizers.

Powders, water dispersible liquids and granules

Wettable powders are finally ground herbicide particles which should be mixed in water. Powders contain clay dilutents, anti-caking agents as well as various types of adjuvants. During application the tank should be agitated continuously in order to prevent settling of the herbicide particles. Due to the nature of powders they cause considerable wear on spray equipment.

Water-dispersible liquids (WDL) and granules (WDG) are similar to wettable powders except that they are already dispersed in a liquid. In most cases WDL and WDG are easier to apply than powders. However, tanks should be agitated continuously to prevent settling of active ingredients.

A big disadvantage of powders is the fact that they are prone to spray drift. For this reason chemical companies do not readily produce herbicides in powders.

Solutions

Solutions are also referred to as water or oil solubles. The appearance of solutions is clear as opposed to emulsions and suspensions. The dissolved solute component is the solute and the dissolving component is the solvent. Water soluble powders require very little tank agitation in order to dissolve the powder whereas liquid water soluble require slightly more. None of them require as much as wettable powders. Once the powder has formatted a solution it does not settle so no further agitation is required.

Additives

Additives are mixed into spray mixtures to increase the effectiveness of the active ingredient. If not used correctly, some additives may cause a decrease in the effectiveness of the active ingredient so sound knowledge about the herbicide and additive is required before adding the two components.

Surfactants are used to modify the characteristics between two liquids which are not soluble or a liquid which rests on top of a solid surface. Surfactants are used in the following situations:

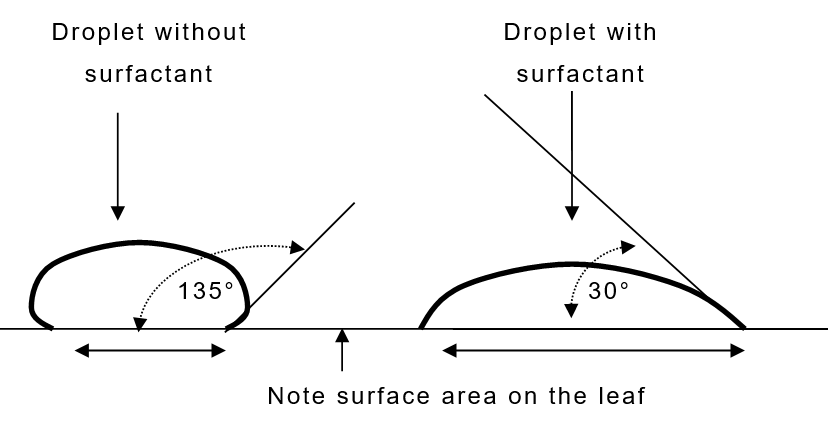

- Spray modifiers: The surfactant usually changes the surface energy or surface tension of the herbicide so that droplets increase the area in which they are in contact with the leaf.

- Activity enhancers: They increase the contact area between liquids which are mixed as emulsions.

- Activity enhancers: Surfactants help to increase the area of contact between the solid phase and liquid phase of suspensions or powders.

- Drift control agents: Increases the droplet size of the herbicide in order to reduce the amount of drift.

- Anti-foam agents: Some herbicides generate excessive foam when mixing. The foam makes it difficult to see how full the tank is and increases the risk of spillage. Anti-foam agents reduces the amount of foam during agitation.

- Compatibility agents: These agents are used when two or more pesticides are mixed which are not compatible without the agent.

The effect of surfactants on the droplet shape and area of the leaf which is in contact with the herbicide. It can clearly be seed that adding a surfactant will increase the area this increasing the effectiveness of the herbicide

Surfactants have different names depending on the purpose for which they will be applied. These are:

- Emulsifiers

- Wetters

- Stickers

- Spreaders

- Dispersers

Surfactants have various interactions with the ions of the active ingredients of the herbicide. These can be as follows:

- Non-ionic: non charged

- Anionic: negatively charged

- Cationic: positively charged

- Ampholytic: positive or negatively charged

Leave A Comment

You must be logged in to post a comment.